The polymer should be selected and designed to achieve the properties required in accordance with the different environments and chemical properties.

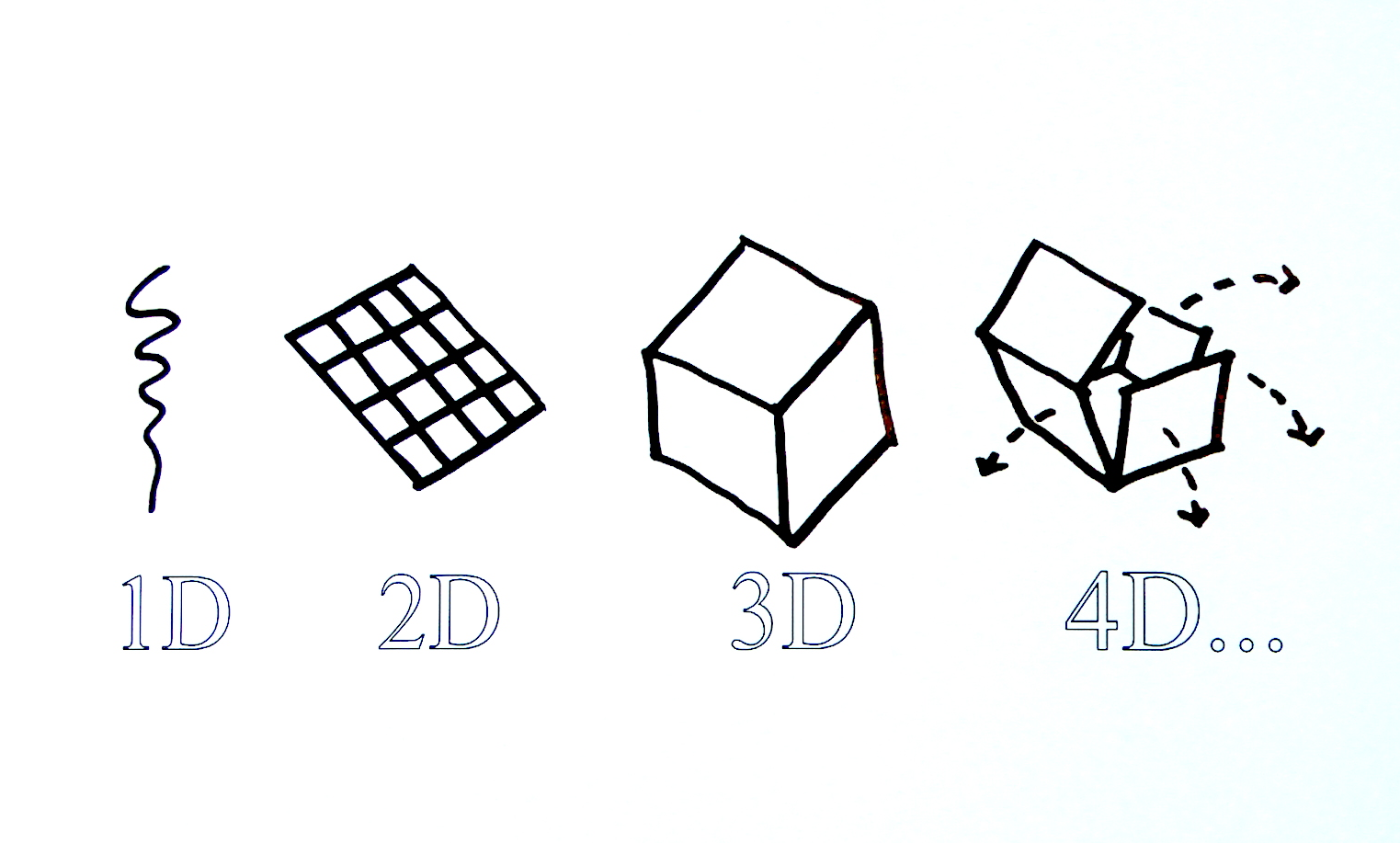

Among them, the self-healing materials used for 3D printing mainly comprise soft active materials (SAMs), as a type of polymer, which can be mainly divided into five parts: engineering plastics (such as polyethersulfone, poly-ether-ether-ketone, and polyphenylene sulfide), bioplastics (such as polylactic acid and polycaprolactone), thermoset materials, photosensitive resin, and polymer gels ( Tan et al., 2020). So far, 4D printing has been used to develop many types of smart materials, such as shape-memory materials ( Cheng et al., 2020), smart gel materials ( Jang et al., 2020), and self-healing materials ( Chen et al., 2016), which demonstrated great applications in the fields of biology ( Aronsson et al., 2020 Kim et al., 2020), medicine ( Javaid and Haleem, 2020 Lin et al., 2021), and bionics ( Correa et al., 2020). 3D printing smart materials, which are also referred to as “4D printing,” change configurations over time. Smart materials have attracted widespread attention due to their shape and properties which can be altered with external environment changes, such as light, electricity, and magnetism ( Wu et al., 2019).

This study confirms that the designed self-healing system has potential applications in many areas due to its excellent self-healing performance, which provides valuable guidance for designing the 4D system. The obtained materials showed excellent repair effect, with a recovery rate of up to 87.22%. Furthermore, we also fabricated the 4D printed material with a tensile strength of 50.93 MPa through a 3D printer. It is worth noting that the mechanical strength of the broken materials can be restored to 35.65 MPa after heating to 130☌ for 2 h to repair the damage, and the self-healing efficiency reached up to 85.06%. The melamine-formaldehyde capsules and latent-curing agents were uniformly distributed in the materials according to the digital photos and scanning electron microscope (SEM) pictures.

In addition, graphene oxide was used as a reinforcing phase through its two-dimensional-layered structure to increase the tensile strength to 41.91 MPa, which is higher than the initial materials. In this study, we used in situ polymerization to make melamine-formaldehyde (MF) resin microcapsules to wrap the epoxy oxide as a repairing agent and Cu(MI) 4Br 2 as a latent-curing agent to protect epoxy oxide E-51 from broken melamine-formaldehyde resin microcapsules. Self-healing materials as a type of promising smart materials are gradually applied to electronics, biology, and engineering.

0 kommentar(er)

0 kommentar(er)